Our company provides customers with water treatment and environmental protection equipment such as cyclone solid and oil removal equipment, dissolved air flotation, ultrafiltration, nanofiltration membrane equipment, reverse osmosis membrane equipment, biochemical treatment, etc. Among them, compact cyclone air flotation and mixed flocculation air flotation are the characteristic products developed by our company; According to different on-site conditions, different processing techniques can be adopted to meet different customer requirements.

1.Air flotation equipment

Our company provides conventional air flotation, compact cyclone air flotation, ozone oxidation air flotation, and mixed flocculation air flotation equipment. At the same time, customized solutions can be designed for customers. For details on compact cyclone air flotation equipment, please refer to the compact cyclone air flotation equipment.

Flocculation air flotation

Cyclone air flotation CFU

2.Membrane separation equipment

Membrane separation is a separation process that utilizes the selectivity of a membrane, with a certain amount of energy difference on both sides of the membrane as a driving force, due to the different migration rates of various components in the solution through the membrane. Membrane separation is the process of separating and purifying substances using a medium with certain selective permeability characteristics. It is a process in which substances are passed through or intercepted, similar to a sieving process, and the purpose of substance separation is achieved based on the pore size of the filter membrane and the size of the substance particles. Our company provides equipment including ultrafiltration, nanofiltration, and reverse osmosis membranes.

PetroChina Changqing Oilfield Project Internal components of ultrafiltration membrane

Reverse osmosis membrane equipment

Integrated automatic control reverse osmosis membrane equipment

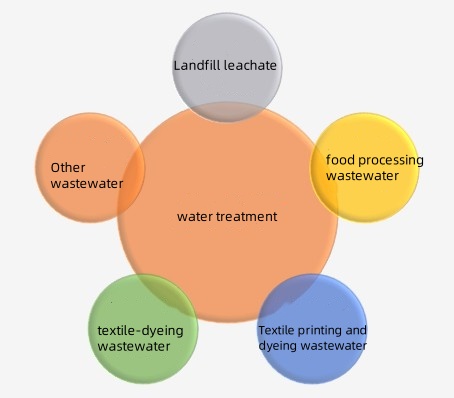

3.Application fields of water treatment equipment

Water treatment equipment can be applied to multiple fields. For example: urban sewage (leachate, kitchen waste water, etc.), electronic wastewater, electroplating wastewater, textile printing and dyeing wastewater, leather wastewater, food processing wastewater, beverage wastewater, hospital wastewater, as well as reclaimed water reuse and other occasions; It can be said that water treatment involves all aspects of social life and production.

The following figure shows the general conventional water treatment process, in which the pretreatment facilities select different processes such as sedimentation, air flotation, and biochemistry according to different situations. After membrane separation, the water quality can basically meet the national standard requirements.

Our company can customize corresponding solutions based on the liquid quality and discharge requirements of customers. Being able to comprehensively consider the initial investment cost, operating expenses, maintenance operations, volume and land occupation, production cycle, etc., and provide the optimal process plan and implementation measures for customers.