Our company provides flue and exhaust gas treatment and sewage treatment process solutions and equipment, including dust collectors, desulfurization and denitrification, VOC treatment equipment; Water treatment includes environmental protection equipment such as cyclone solid and oil removal, dissolved air flotation, ultrafiltration nanofiltration membrane equipment, reverse osmosis membrane equipment, etc.

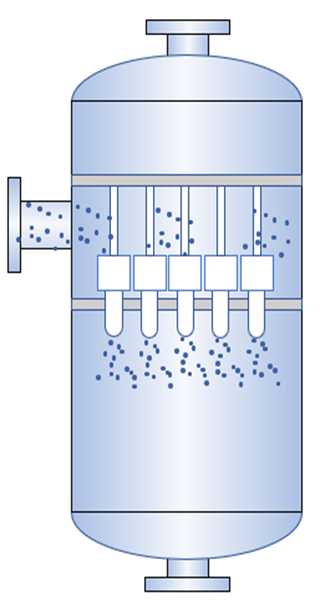

1. Micro cyclone tube dust collector

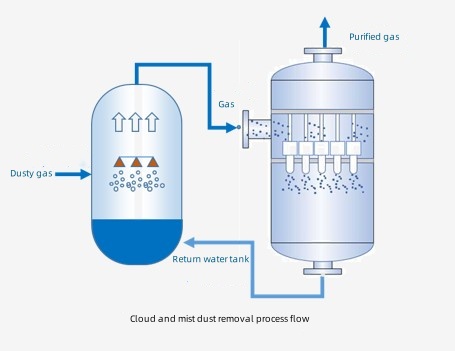

The micro cyclone tube dust collector is composed of multiple micro cyclone tubes inside, which perform cyclone separation on particulate matter. For details on the micro swirl tube, please refer to the separation internals. The front end of the dust collector can also be equipped with a spray device to gather and condense particles, which can achieve higher separation efficiency.

Spray+cyclone dust removal process is shown in the figure, and the overall system is called cloud and mist cyclone dust removal system. The cloud in the spray area gathers and condenses the particles to form larger particles, so as to achieve the purpose of more efficient separation.

2.Wet vortex generator

The vortex generator system can be used for dust removal, desulfurization, denitrification and other purposes. The core components of the equipment adopt advanced gas purification technology imported from Russia.

● High efficiency

● Low pressure drop

● Compact structure

● Recycled water, greatly saving water

● According to different functions, on-site dust removal, desulfurization, denitrification, etc. can be carried out

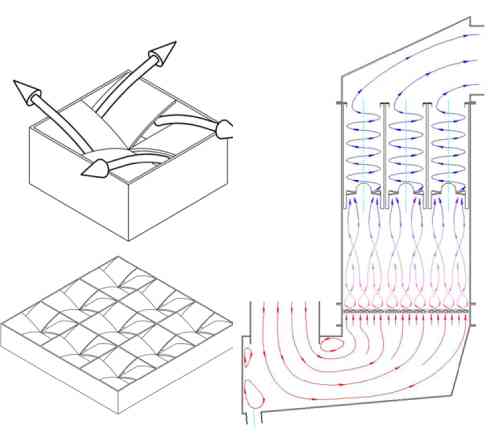

2.1Vortex generator system

The vortex generator system includes single vortex generator and multi vortex generator. The single vortex generator consists of a water tank, vortex generator, control system, and circulation system (as shown in the figure). Add chemicals to the water tank according to different purposes to achieve better results.

Single vortex flow vortex generator

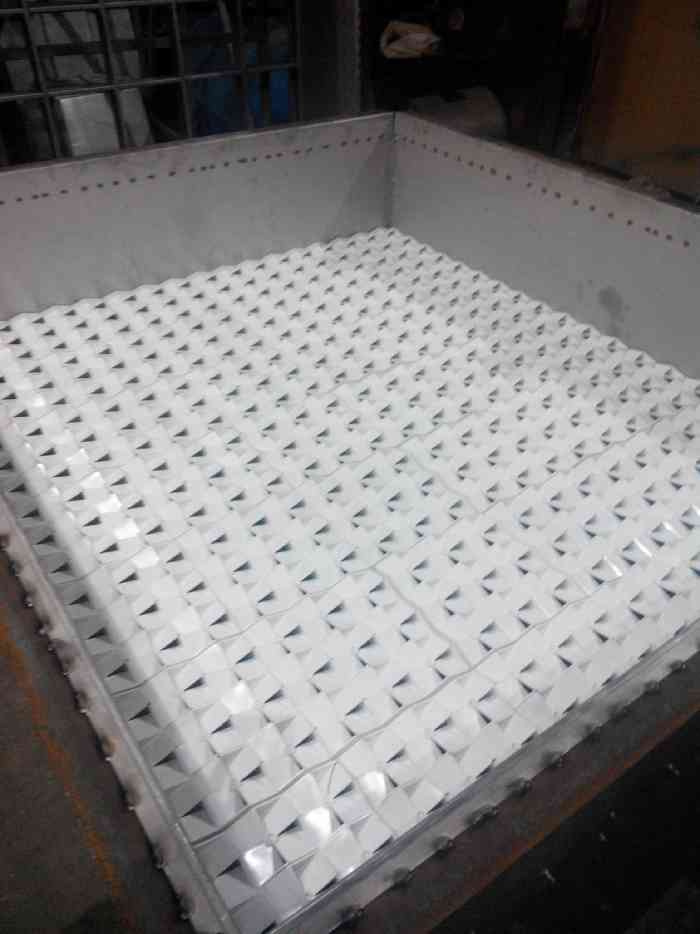

The multi vortex generator (grid type) has a vortex plate layer composed of single vortex elements in parallel, which guides the airflow to form multiple small rotating vortices, which are in close contact and mixed with the liquid; The vortex plate layer can also be set in multiple layers according to specific working conditions to achieve the expected effect. The multi vortex generator water tank is located at the bottom of the equipment, and the liquid is circulated and sprayed by the control system and circulation system.

Multi vortex generator

2.2Umbrella vortex generator

Umbrella vortex generator is a more compact structure that can be used on the upper part of a conveyor belt for hanging purposes. It has an external water source and louvers for ventilation.

3.Vortex generator combination in series

The combination of grid vortex generator and single vortex generator achieves the effects of efficient washing, efficient contact reaction, and efficient cyclone separation. The on-site operation situation of Sinopec enterprise is shown in the following figure.

Due to the use of swirl technology in the equipment, it has the advantages of small size, high efficiency, low clogging, simple maintenance, and low cost. The equipment can simultaneously achieve four functions of dust removal, desulfurization, denitrification, and white smoke elimination, making it an efficient reaction separation device that integrates multiple functions.

There are numerous cases of vortex purifiers in Russia, used in chemical production (gases, steam), coal-fired power plants (Sox, fly ash), diesel power plants (Sox, Nox), gold mining (HCN), aluminum mining (Sox), and coal mining (dust).

Eddy current technology combined with gas purification equipment

4.Other gas purification equipment

Our company also provides gas purification equipment such as bag filters, gas filters, and activated carbon adsorbers. Combining with vortex purifiers to create different solutions that meet customers’ different process requirements.

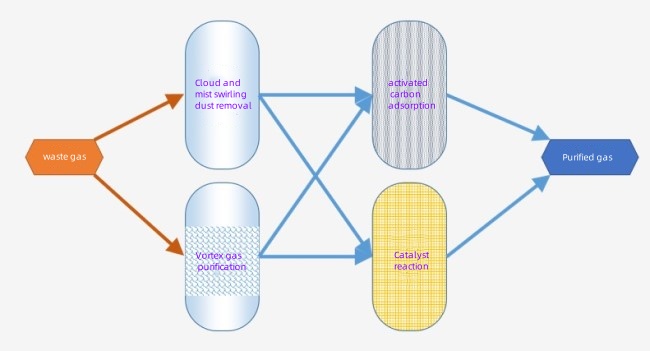

5.Gas purification process plan

We adopt different process facilities and provide comprehensive solutions for exhaust gases of different customers and situations to meet their technical requirements. The general process flow is shown in the figure.

For example, to remove particulate matter, a combination of cloud and mist cyclone dust collectors or vortex dust collectors can be used, and only water can be added to the water tank. The minimum particle size that can be removed is 1 μ m, and the equipment has no blocking parts, no need to replace, and simple and convenient maintenance. If there are sulfides, nitrogen oxides, VOC gases, different agents can be added to achieve washing and separation. After the vortex generator, it can be combined with adsorbers, catalytic reactors, etc. to achieve more precise requirements.