Compact Oil-Water Separator

Our cutting-edge technology for l-liquid compact (in-line) separation is developed based on current cyclonic separation. They feature high separation efficiency, flexibility and providing a solution with compact installation without sacrificing separation performance.

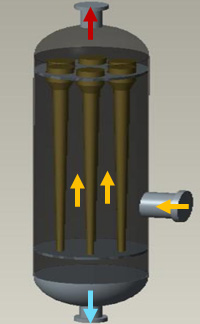

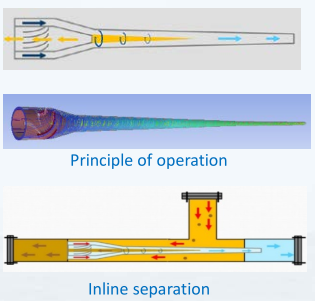

The compact separation technologies consist of Dewater, Hydrocyclone (HC). Both of them adopt the principle of axial flow cyclone. These technologies provide a full separation coverage from oil well to produced water treatment.

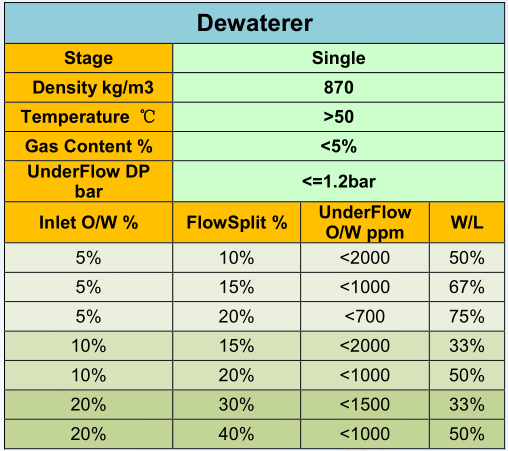

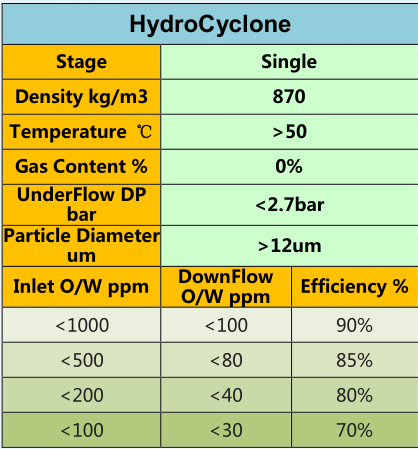

Dewater is suitable for separation applications for inlet oil content up to 50%. Hydrocyclone is used for applications where the inlet oil content is less than 1000ppm. Based on specific operation conditions, both Dewater and Hydrocyclone can be adjusted with their geometric parameters for optimized performance.

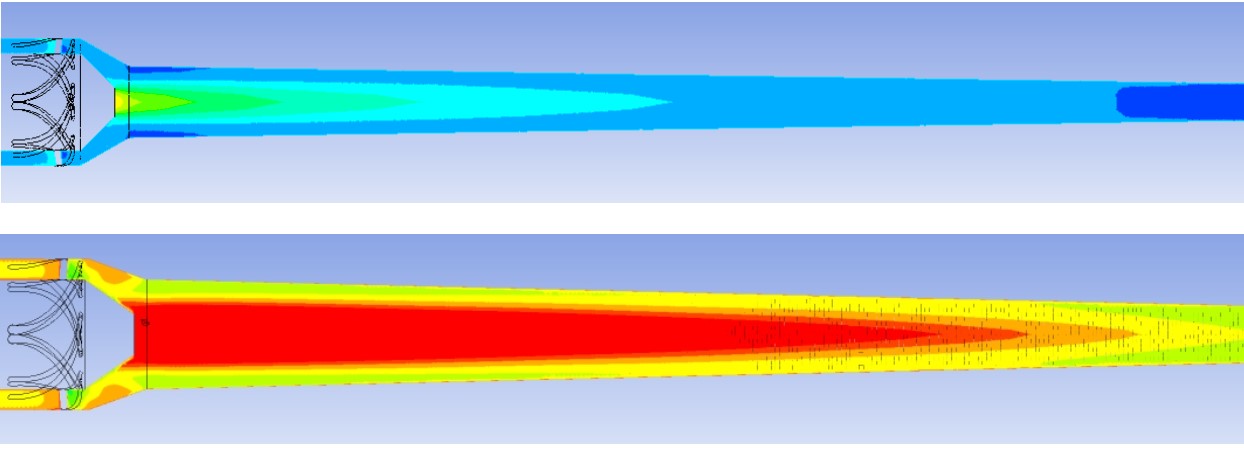

The compact (inline) oil-water separator mainly uses the principle of centrifugal separation. The liquid enters the cyclone (axial swirl) from the inlet flow channel axially, and forms a stable swirl flow to generate high centrifugal force (more than 100g) through the vane (special optimized design), so that the oil and water are separated in the cyclone. The compact separators features very short residence time (less than 10s). Their separation efficiencies are over 90%. Repeated and reliable CFD simulations and site tests have been carried out for separartion optimization and verification.

The product can be applied to the production at wellhead, central process facility (CPF), refinery and chemical plant. Some typical process are presented in the section of Compact Separation Solution.

Performance:

● Dewater: Water outlet Pressure Drop <1bar, Oil in water <1000ppm.

● Hydrocyclone HC: Water outlet Pressure Drop < 3bar. Separation efficiency is 90% for oil droplet of 10 micons and larger.

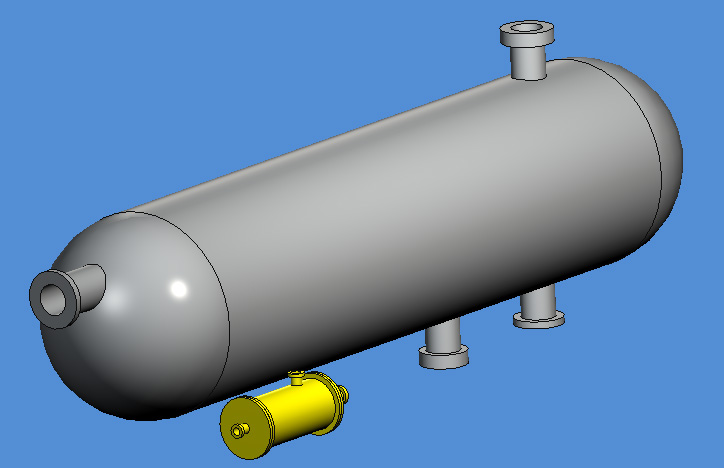

● Flexibility: two or three stage compact separators can be combined to form different Process Solutions. -Compact Process Solutions

Dewater Performance Hydrocyclone Performance

Liner:

Picture for Liner

CFD Analysis for Liner

Assembly Method:

MULTI Liners Single Liner

Product Advantage:

● Very compact in size and small footprint. The single-stage residence time is <10s, and the three- stages residence time is <30s. Suitable for new installation and retrofitting of exist equipment that require better performance or higher capacity.

● Small pressure drop. The pressure drop of Dewaterer (BC) at water outlet is less than <1bar.

● High efficiency. For feed with 30% oil, oil in water (OIW) will be less than 1000ppm with Dewaterer (efficiency > 99%). The separation efficiency of combined separation train of Dewater and hydrocyclones will be achieve 99.9%, such as from 30% oil content to under 50ppm OIW.

● Liquid Weight, Low Investment Costs

● SKID Equipment, easy to install

● Simple Design, Less Operation and Maintenance Cost

● Different Solution:A variety of solution options to adapt to different site conditions. See the Advanced Process Solution for details.

Conventional Separation .VS. Advanced Separation