Advanced technology is a technology that makes full use of supergravity swirl technology compared with conventional technology to shorten residence time, improve separation efficiency and reduce equipment volume.Advanced technology can be used for new oilfield development projects;At the same time, for high water-cut oilfield (where the existing equipment cannot meet the process requirements), it has great advantages to carry out process optimization.In the retrofitting of high water-cut oilfield, a new type of separation equipment -- compact separation equipment is adopted to meet the process requirements proposed by customers.The equipment has the advantages of small footprint, high efficiency, easy installation and no maintenance.

A few typical solutions are presented for better understanding of OTO compact separation technology.

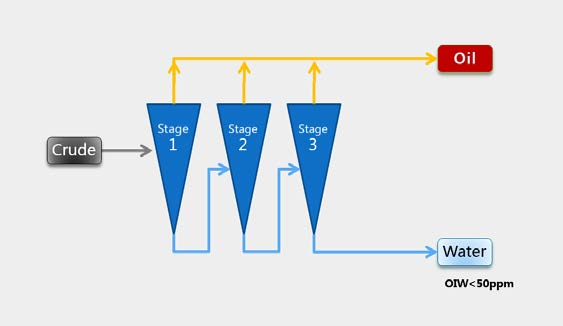

Three stage separation (DW+HC1+HC2) is arranged in series. HC1 and HC2 are both hydrocyclone but with different separation purposes. After three stages of separation, 80%~95% of the water in the feed stream is removed.The oil content in water of the final stage will be less than 50ppm. The following is some relevant experimental data. Total pressure drop the system is about 6 bar. And it can be adjusted according to the requirement of the client. The produced liquid of this process can meet the field re-injection standard. Residence time is less than 30 seconds.

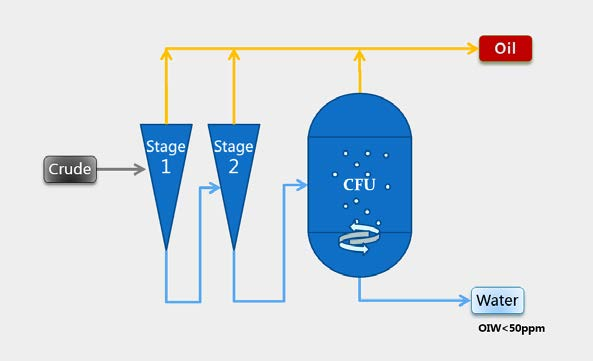

Three-stage in series of DW+HC+CFU , The inlet contains <30% oil. After three stages of separation, 80%~95% ofthe water in the produced liquid is removed. The final water outlet contains will be <50ppm oil and suspended solids.

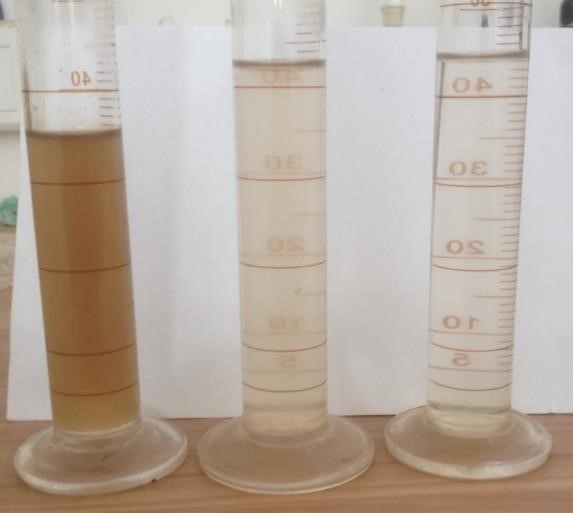

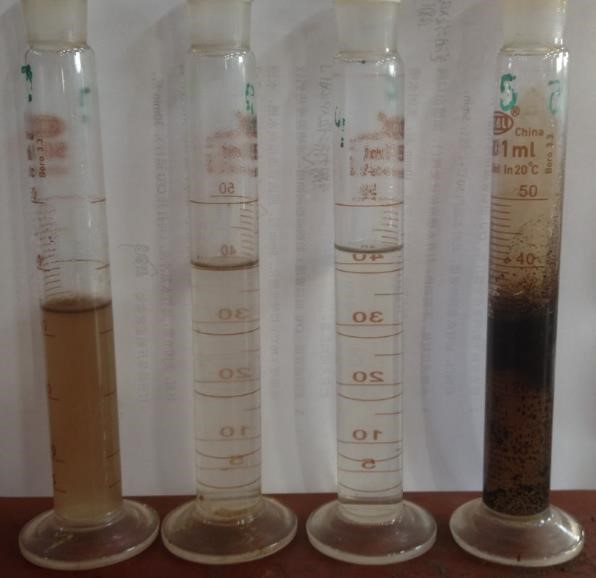

The pictures below demonstrate the separation performance of CS-2. The feed liquid contains 5%-10% of oil.Stage DW, the oil contents in water outlet is about 500ppm. Stage HC, it is 50-100ppm. And stage CFU, it can even be reduced to 15-30ppm. The oil outlet is about 30-40% oil. Under standard operation condition, the pressure drop of each stage is 1bar, 2.7 bar, and <1bar respectively. In special cases, the pressure drop can be increased or decreased according to customer operation requirements. This solution is a very suitable choice for on-site re-injection of produced water.

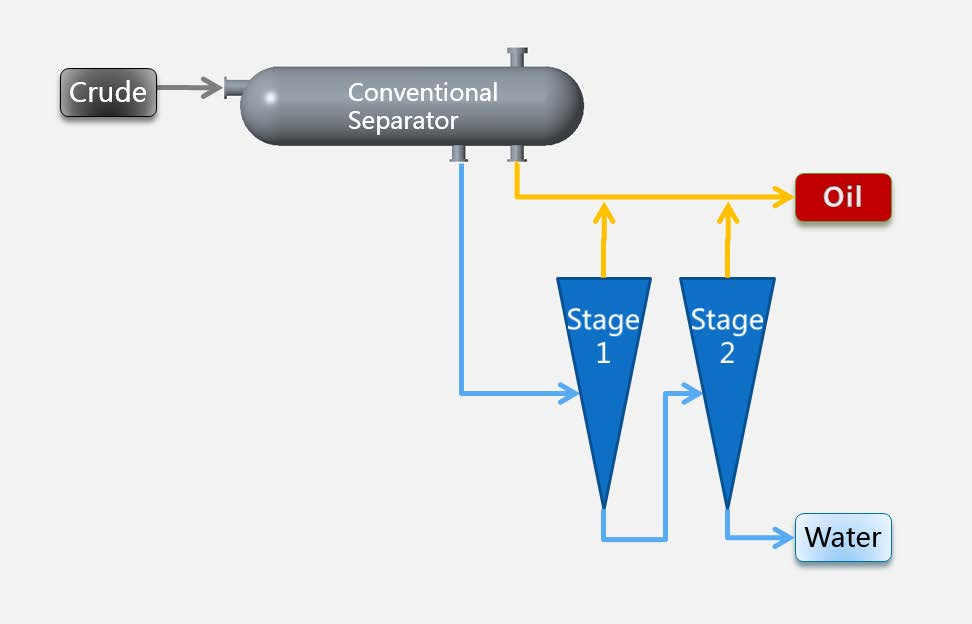

The two stage(DW+HC) are connected in series with the upstream separator(conventional separator). The oil content of the inlet liquid is less than 1500ppm, after separator, less than 50ppm.

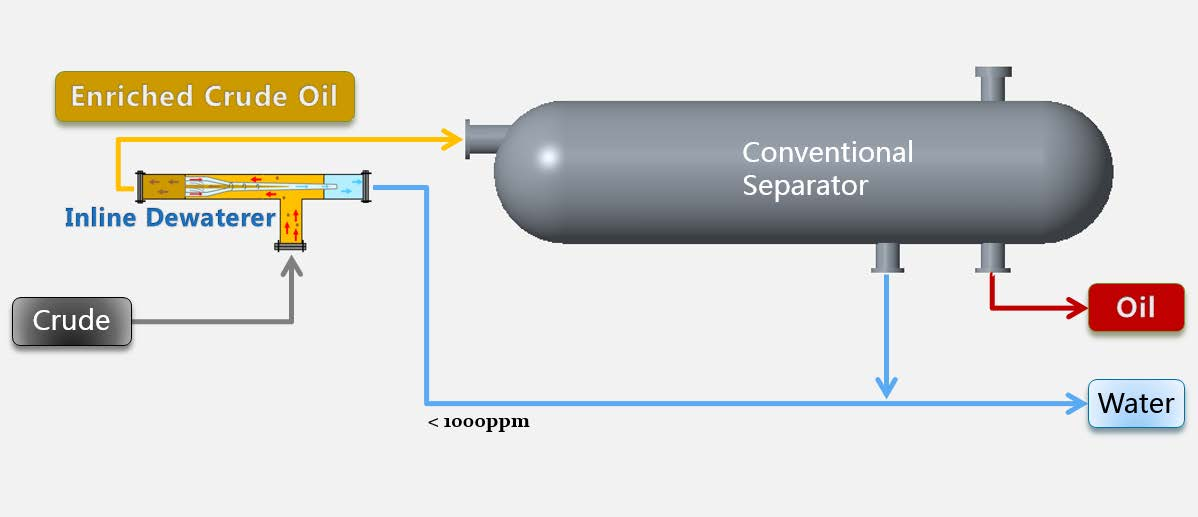

The Dewaterer is installed upstream conventional separator(DW+Conventional separator). Partial water is separated from feed stream before entering separator. The oil content in water stream from Dewaterer will be less than 1000 ppm. Water from Dewater will combine together for further water treatment.

This solution will increase process capacity of separator. It can be used for new installation and retrofitting of existing equipment.