The compact separation equipment independently developed by our company has demonstrated excellent separation performance and stable continuous operation capability during indoor experiments. In order to further explore the separation ability of the equipment for crude oil production fluids, our company cooperated with a certain oil service company in Shengli Oilfield and conducted a pilot test for several months. The final experimental results showed that our company's self-developed compact separation equipment can effectively separate crude oil production fluids. Without adding any chemicals, the treated water quality can fully meet the discharge standards, and the content of oil and suspended solids in the water is less than 50ppm. The pilot test was a complete success.

In order to ensure the fluidity of crude oil in this experiment, an electric heater was installed inside the oil-water mixing tank, with a temperature controlled at 50-70 ℃. The compact separation equipment adopts a multi-stage series connection and integrated pry mounting method. The actual product is shown in the following figure.

In order to ensure that the suspended solids content of the treated water meets the standard, a compact cyclone air flotation unit (CFU) was used after the compact separation process, as shown in the following figure.

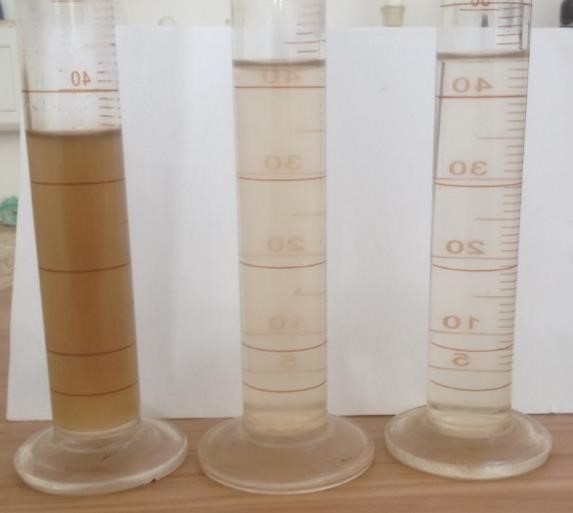

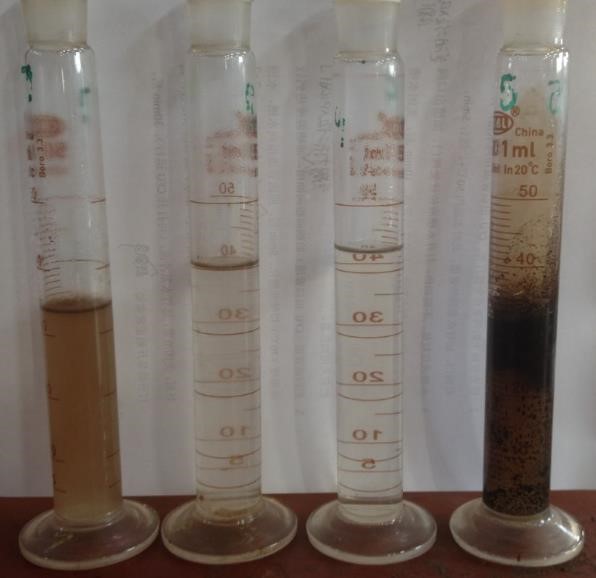

The experimental results show that for crude oil extract with an oil content of 5%~10%, the oil content at the outlet of the three-stage compact separation water is between 20~40ppm. The water samples at the outlet of the first, second, and third stages are shown in the following figure. If a two-stage compact separation and CFU series arrangement is adopted, the final water outlet oil content will be between 10-25ppm, and the suspended solids content will be around 20ppm.

Comparison of water quality at the first, second, and third level water outlets and oil-water mixture at the rightmost inlet

The pilot test successfully achieved the experimental goal of multi-stage compact separation or compact separation combined with CFU series treatment process, and the final water quality can meet the discharge standards of the oilfield, providing strong support and reference for the improvement and promotion of the equipment in the future.